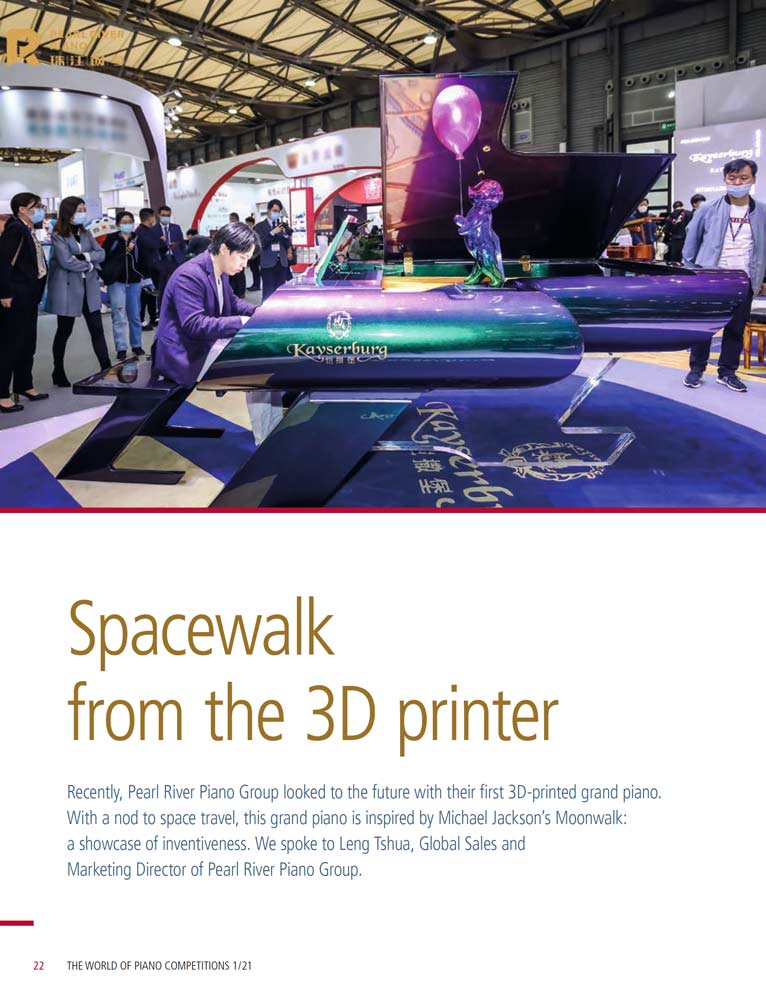

Recently Pearl River Piano Group looked to the future with their first 3D-printed grand piano. This grand piano, a showcase of inventiveness, is inspired by Michael Jackson’s Moonwalk. PIANIST in conversation with Leng Tshua, Global Sales and Marketing Director of Pearl River Piano Group.

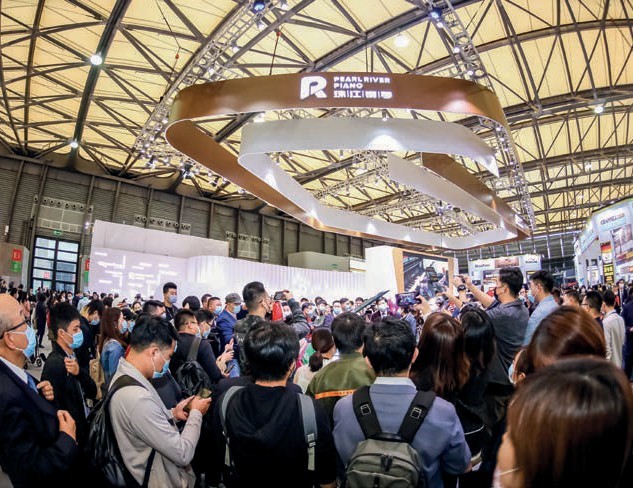

The grand piano was unveiled at Music China, Asia’s largest music trade show. The four-day event in Shanghai attracted more than 11,000 visitors from 81 countries. Kayserburg “Celestial Harmony Spacewalk” stole the show among the 2,252 exhibitors from 31 countries. Founded in 1956, Pearl River Piano Group is now the largest piano manufacturer in the world, producing more than 150,000 instruments per year and a market share of a good 30 percent worldwide. Pearl River Piano Group produces three brands: Pearl River, Ritmüller and Kayserburg.

The process of 3D-printing is revolutionary because it allows designs that are difficult to construct using traditional manufacturing methods. While the piano’s cast iron frame and wooden structure remain unchanged, the cabinet is now printed from carbon fiber polyester. This “Celestial Harmony Spacewalk”, is based on the Kayserburg GH188A and highly advanced CNC processes are combined with 3D-printing technology.

How did the idea come about?

We have been thinking about the 3D-production potential for several years now.

You took car manufacturing as an example, which based itself on the aviation industry. Is looking beyond your own industry typical of genuine innovations?

We certainly need to look beyond the piano industry to make the transition into the new millennium smoothy, as our end users are very different now from 60 years ago. The new generation of consumers has been brought up with their smartphones, and we also need to integrate a technology platform into our future products.

Self-driving cars were long rejected as ‘impossible’. That also seemed the case for a 3D-printed grand piano? How far do you think this evolution will go?

Many things that were considered ‘impossible’ thirty years ago are now part of our daily life. See how fast the smartphone has developed and now we can no longer do without it! We are always looking for new technology that could improve our production process.

Can we say that this is the ultimate step in piano design, a result of previous developments including carbon, or just the next step, because we don’t know where creativity and inventiveness will take us in the future?

Given the endless potential of 3D-printing technology, our first step is to test the manufacturing capabilities of acoustic instruments with such high-tech technology. And if this becomes a reality for the foreseeable future, it could potentially spark a positive revolution in the industry.

As you know the design and manufacture of the rim is something that sets major piano brands apart from others, I just need to mention the huge difference between Bösendorfer and Steinway, for example, which directly results in a different sound concept. How do you see this development in that context?

It is true that the rim, along with other parts of the piano, is vital in the construction and we are very selective in this process as our ultimate goal remains to produce a great sounding acoustic piano.

How does 3D-printing affect the sound of the instrument?

The piano we launched at Music China 2020 was played by professional musicians and other industry experts, and the feedback was very positive, so I considered this experiment a success.

Is production easier? For example, less time-consuming, involving fewer professionals?

The 3D-printing technology certainly made production much ‘easier’ and also faster. But our workers are still needed and they work in perfect harmony with machines, in heavenly harmony I would almost say!

Does this also influence the feeling and the appreciation that customers will have for the instruments? Many still experience the piano as an instrument with a soul that goes beyond its function to produce sounds.

We are well aware that we are makers of acoustic pianos, our intentions are always focused on keeping the soul alive and well!

Do you see 3D-printing becoming a standard in piano production at Pearl River?

Since we have just started with the first step towards a futuristic concept, we are now investigating the market potential after Music China 2020. I think that in the coming years we may be able to do realistic projections about 3D-printed pianos.

Can this also be used in upright pianos in addition to grand pianos?

Certainly! For this design we also use plexiglass, and we are currently looking into other materials suitable for acoustic properties for the piano.

How many pianos are being produced?

We don’t have a projection of that yet, but we look forward to the interest in this.

Can we see a printed piano in Europe soon?

I certainly expect that!

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |